PTFE – N is an unfilled grade of Polytetrafluroethylene (PTFE). This natural grade of PTFE contains no fillers and has almost a complete chemical resistance. It combines effective insulating capabilities and high dielectric properties.

Polytetrafluroethylene (PTFE) is a synthetic fluoropolymer which finds numerous applications. PTFE is most well known by the DuPoint brand name Teflon®, PTFE shares the properties of fluorocarbons. Therefore water and water-containing substances like most foods do not wet PTFE, as adhesion to PTFE surfaces is inhibited. Due to this property PTFE is used as a non-stick coating for pans and other cookware. It is very non-reactive, and so is often used in containers and pipe work for reactive and corrosive chemicals. Where used as a lubricant, PTFE reduces friction, wear and energy consumption of machinery. The coefficient of friction of plastics is usually measured against polished steel. PTFE’s coefficient of friction is 0.03“ 0.1, which is the second lowest of any known solid material (Diamond-like carbon being the first).

Material Properties

PTFE has excellent dielectric properties. This is especially true at high radio frequencies, making it suitable for use as an insulator in cables and connector assemblies and as a material for printed circuit boards used at microwave frequencies. Combined with its high melting temperature, this makes it the material of choice as a high-performance substitute for the weaker and lower melting point polyethylene that is commonly used in low-cost applications. Its extremely high bulk resistivity makes it an ideal material for fabricating long life electrets, useful devices that are the electrostatic analogues of magnets. Because of its chemical inertness, PTFE cannot be cross-linked like an elastomer. Therefore it has no “memory,” and is subject to creep (also known as “cold flow” and “compression set”). This can be both good and bad. A little bit of creep allows PTFE seals to conform to mating surfaces better than most other plastic seals. Too much creep, however, and the seal is compromised. Compounding fillers control unwanted creep and improve wear, friction, and other properties. Sometimes metal springs apply continuous force to PTFE seals to give good contact, while permitting some creep. Due to its low friction, it is used for applications where sliding action of parts is needed: bearings, bushings, gears, slide plates, etc. In these applications it performs significantly better than nylon and acetal; it is comparable to ultra high-molecular weight polyethylene (UHMWPE), although UHMWPE is more resistant to wear than Teflon. For these applications, versions of Teflon with mineral oil or molybdenum disulfide embedded as additional lubricants in its matrix are being manufactured. Formulations of PTFE include infusions with glass, carbon and bronze and other fillers, giving it added properties while allowing it to retain most of its unique characteristics.

Applications

-

Mechanical Seals

-

Envelope Gaskets

-

Bearing

-

Vee Rings

-

Chemical Linings

-

Electrical Insulators

-

Packings

-

Laboratory Equipments

Key Features & Benefits

-

Excellent Low Friction

-

Chemically Inert

-

Outstanding Electrical and Dielectic Properties

-

Low Dimensional Stability

-

Non-stick and Release Properties

-

High Thermal Stability

-

Poor Wear and Mechanical Strength

-

Easy to Machine

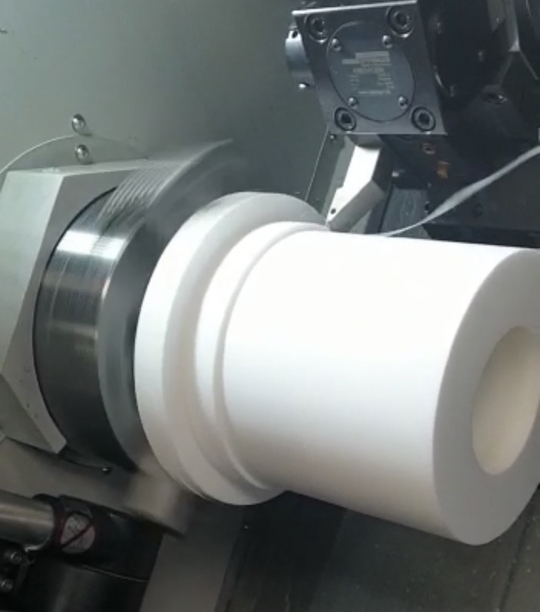

Shapes Available

Sheet

Rod

Moulded Cylinder

NEED MORE INFORMATION, PRICING OR SPECS?

If you would like more information please contact us today and one of our friendly team will respond.

CONTACT US